CSUH-INDIA TECHNOLOGIES PVT LTD

CSUH is a Global Engineering and Technology Solutions Company. We enable our customers to apply technology imaginatively across their value chain to solve problems that matter. We are committed to designing for tomorrow, together with clients.

We have an engineering and problems solvers by nature. We apply our domain and technical expertise to help customers design, Build and Maintain world-class products. Our core engineering capabilities, focus on technology and innovation, and passion for excellence help us create value for some of the most respected brands in their respective industries.

"OUR MISSION"

We always make an effort to deliver the quality work and innovative solution to our valuable client’s in the areas of engineering services.

"OUR VISION"

To be the leading company in providing innovative, High value engineering services to global corporations in an effective and economic price. It is our aim to be counted amongst the most respected companies globally in the arena.

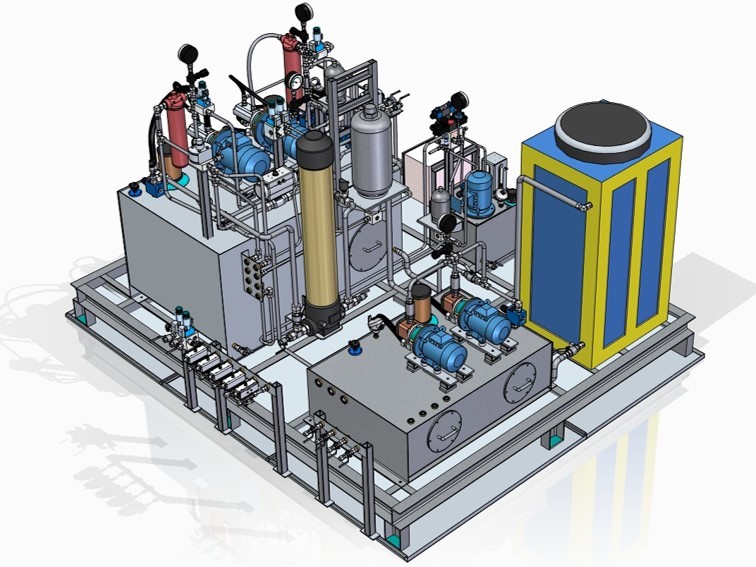

"HYDRAULIC SYSTEM DESIGN"

We will provide engineering services to build Hydraulic Power Pack, Manifold, Pipe Routing for different applications like steel mills, Power projects and Machine tool and Other applications. A complete design solution from consultation of hydraulic circuits to equipment design. Creation of 3D model, General assembly drawings and manufacturing as per design standard.

We have a industrial experience with domain knowledge of Design Of PRESSURE VESSELS, Special equipment’s and mechanisms of HIGH VACUUM SYSTEMS, Design and fabrication of high vacuum process equipment for THIN FILM DEPOSITION, Design of HYDRAULIC POWER PACK and sheet metal products using Advanced CAD tool SOLID EDGE-2021 and AUTO CAD etc.

- Design and development of hydraulic circuits, power units pumping units and manifolds for steel mills, power projects, machine tool, oil and gas projects.

- Design of pipe routing and layout design for hydraulic power units.

- Performs all the necessary calculations required (as per ASME STD) for construction of total system.

- Explicit user of multiple CAD packages, good knowledge in GD&T ASME Y14.5 drafting standards and manufacturing drawing creation.

- Design of supporting structures, hydraulic tanks and frames.

- Expertise in design, modeling and detailing using CAD software’s.

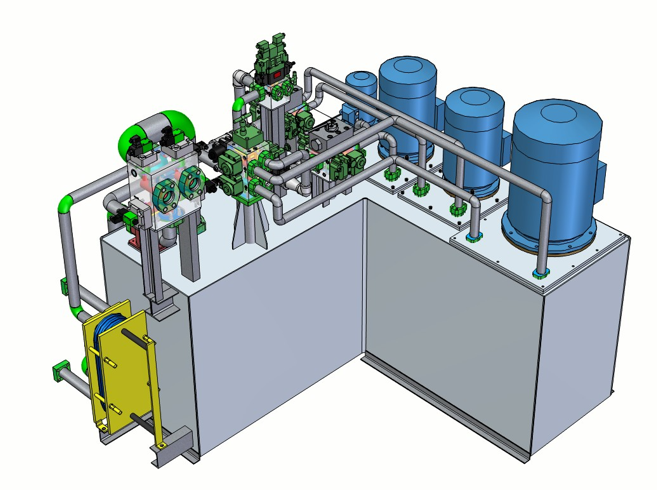

LUBRICATION SYSTEM FOR ROTOR BEARING:

We are your contact for any kind of lubrication system such as Gear Lubrication, Bearing Lubrication, Central Lubrication and Engine Lubrication.

We deliver from standard lubrication units up to combined high and low pressures lubrication system

Bearing lubrication plays a critical role in the lifespan and performance of bearing it helps separate parts moving in order to minimize friction and prevent wear.

In addition to providing that separation, it also dissipates friction heat (Which prevents overheating and deterioration of the lubricant) and protects against other known issues like corrosion, moisture and other contaminates.

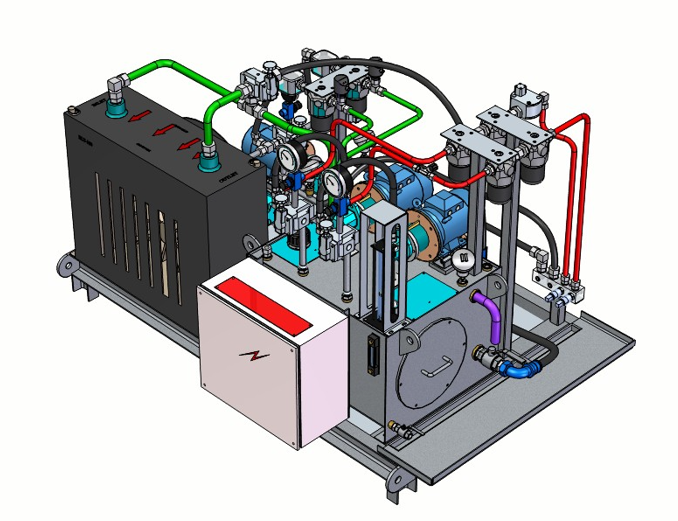

HPU FOR LUBRICATION :

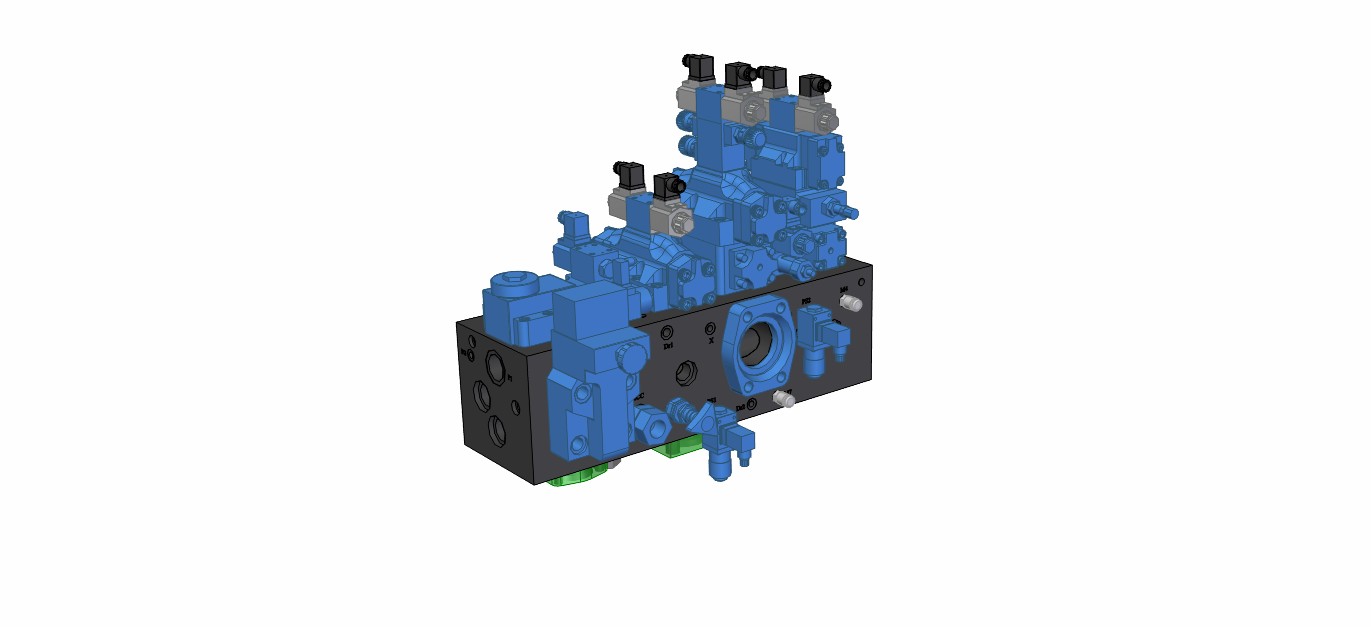

A HYDRAULIC POWER PACK is a self-contained unit that consist of a Motor, Reservoir, Pressure/Directional/Flow Control Value, and a Hydraulic pump, these all play major roles in generating a massive amount of power, which helps to drive hydraulic machinery.

With our experience and expertise, we’ll be able to serve our clients as per their requirements.

Power pack Unit also named as a Hydraulic Motor is the backbone of any hydraulic system, when nowadays, has a huge demand in several industries including Agricultural, Construction and Automotive.

A well designed and Manufactured cylinder is all you need to ease the working and boost productivity and if you invest in the quality, it would give returns in the long run. Keeping this in mind, one of the preeminent HYDRAULIC and Power Pack Unit.

CUSTOMIZED HYDRAULIC POWER PACKS

Test RIG For Hydraulic Value : High Pressure (350 BAR)

HPU For Chip Compact (High Pressure)

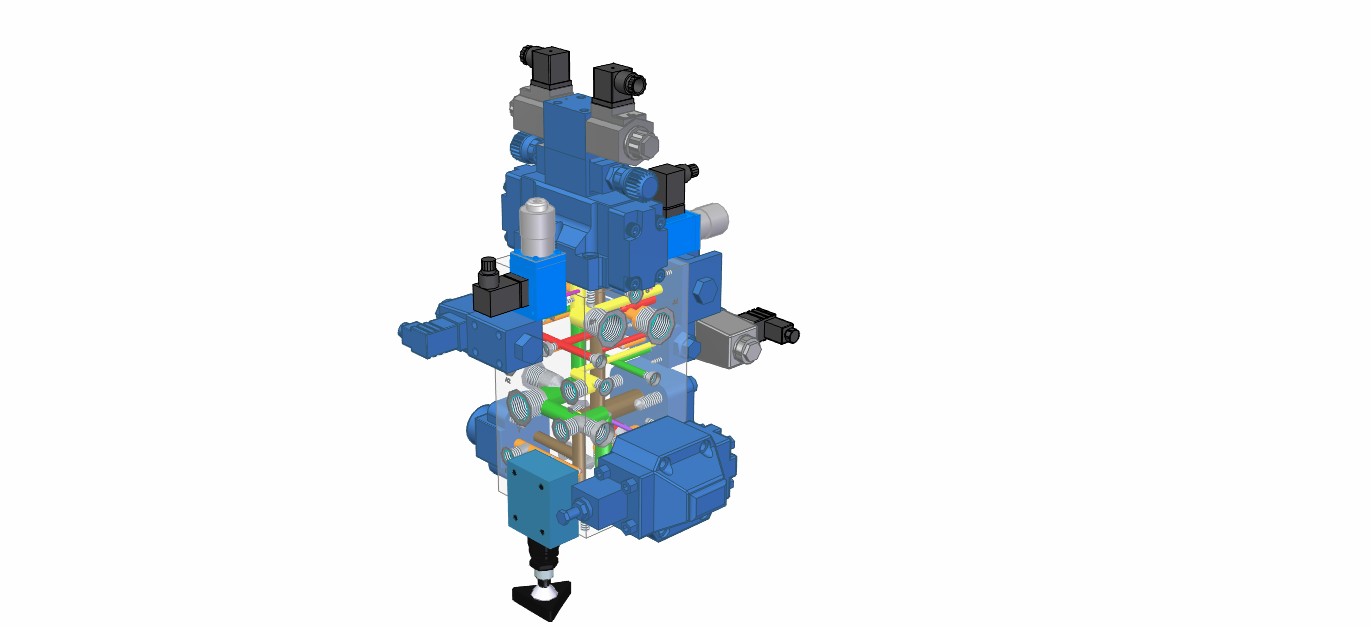

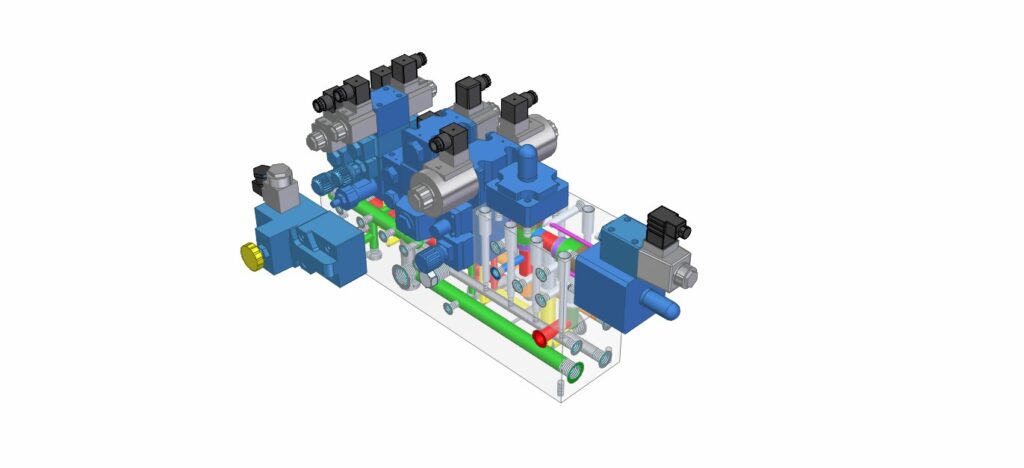

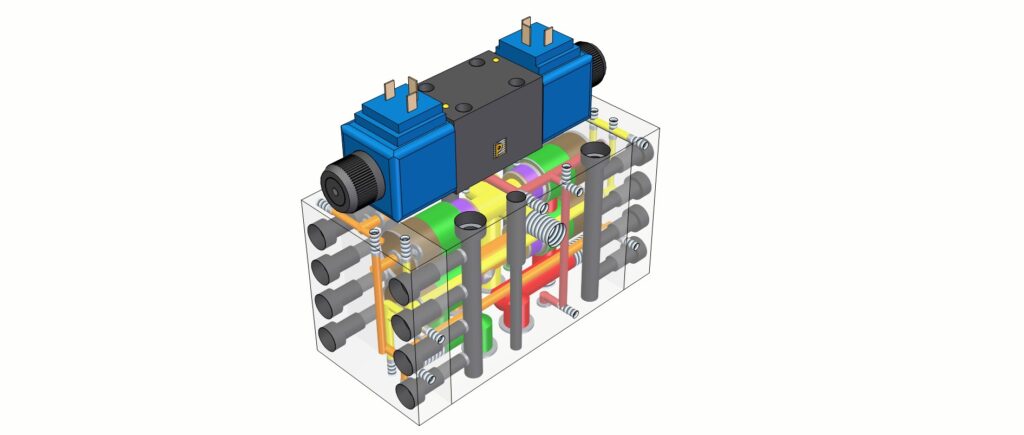

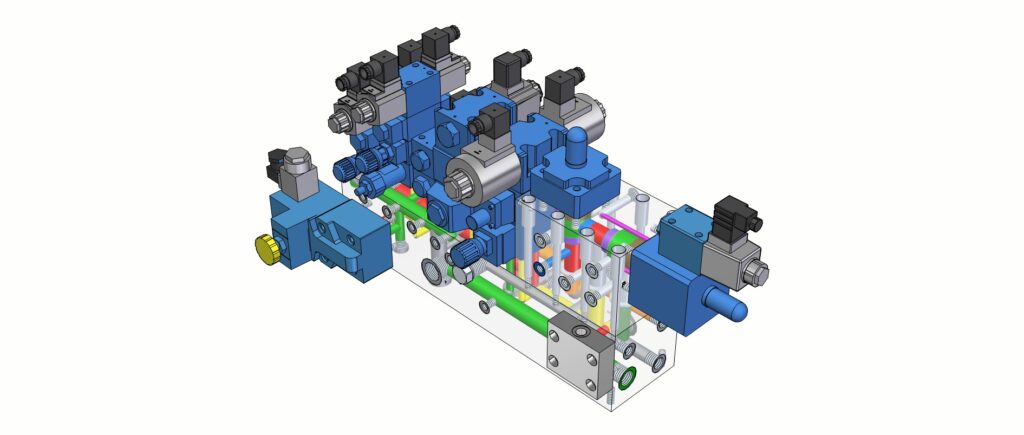

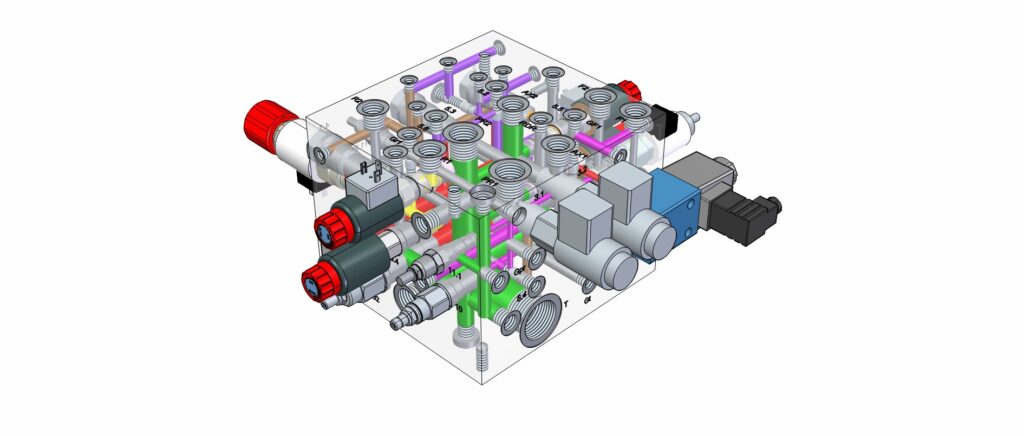

"MANIFOLD DESIGN"

- A Hydraulic Manifold is a COMPONENT in the hydraulic system that serves as a distribution hub for fluid flow. Its a block-like structure that contains Channels, Ports and Values that direct and control the flow of hydraulic fluid from the pump to the various hydraulic actuators and devices in the system.

- We are doing the CAD Design work. The design is based on the customer’s requirements and preferences. We are using the latest tools and techniques to ensure the accuracy and quality of the design. The final product will be ready for production. Our team is composed of CAD expects with extensive experience in the industry. We guarantee a high-quality product and excellent customer service. We are confident that you will be satisfied with the end result.

- We are committed to delivering the product within the agreed time frame. We strive to exceeds customer expectations and deliver a product that meets their needs and exceed their expectations. We guarantee a satisfactory outcome.

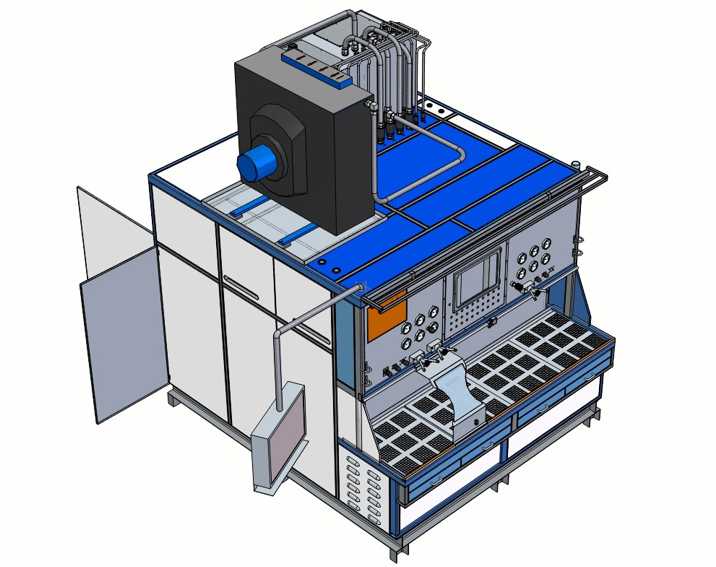

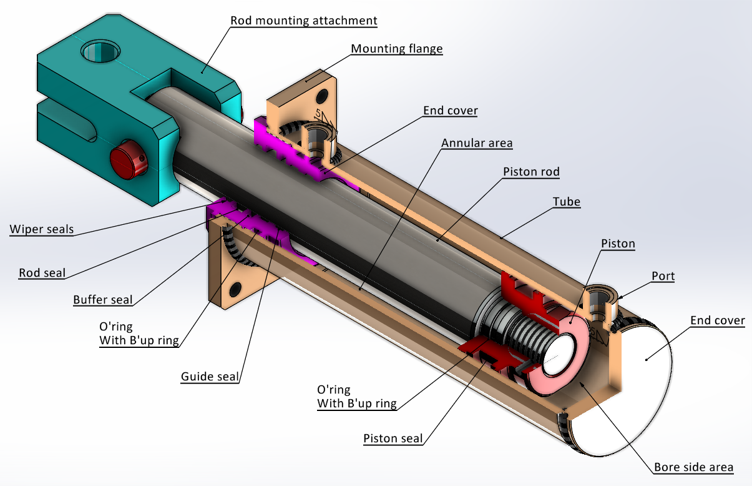

"CYLINDER DESIGN"

HYDRAULIC CYLINDER

Bucking resistance as defined by Euler must be taken into consideration when deciding on piston rod diameter and stroke length. Manufacturer’s tables are available for this. when installing the cylinder, it is necessary to insure that no distortions are possible. In addition, the direction of force must be effective in the axial direction of the cylinder.

Force calculation of cylinder, Force(F) = Pressure(P) x Area(A)

From this equation we can decide the bore diameter of the Cylinder by equating force and pressure.

The Permissible buckling force fperm a pressurised load is calculated as follows :

Fperm =[π2. E. I/lk2. v]

E = Elasticity Module [daN/cm2] (for steel = 2.1 • 106)

I = Area Moment [cm4] (for Φ = d4 • π/64 = 0.0491 • d4)

LK = Free Bucking Length [cm], v = Safety Factor 2.5 – 3.5